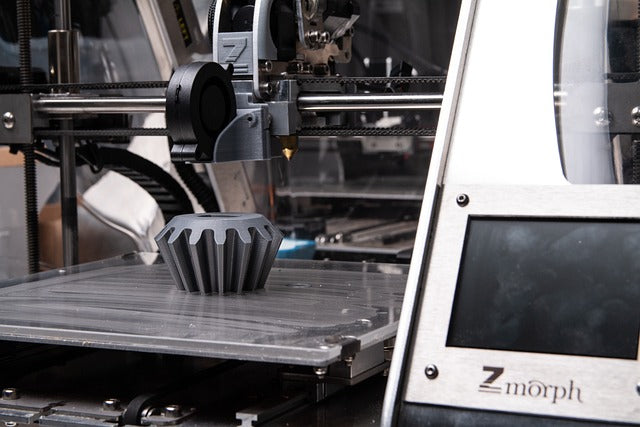

FDM Printing

Fused Deposition Modeling (FDM) is a popular 3D printing technology that creates objects by extruding molten plastic layer by layer. It's great for creating functional prototypes and parts quickly and affordably.

PLA

Derived from renewable resources like corn starch or sugarcane, PLA is a popular biodegradable material. It offers ease of use, good surface finish, and low warping, making it suitable for a variety of applications including prototyping, hobbyist printing, and education. Compared to other materials, PLA has a low melting point, allowing for easier printing without the need for a heated bed. However, it has limited durability and may degrade over time with exposure to moisture and heat.

Benefits of PLA include being environmentally friendly since it's biodegradable and compostable. It's also easy to print with due to its low printing temperature and minimal warping. Moreover, PLA is available in various colors and finishes, making it versatile for different types of prints.

On the other hand, PLA isn't as heat-resistant or strong as other materials like ABS or nylon. It's also more brittle, which can result in issues with layer adhesion and durability. Additionally, PLA has a lower melting point, making it unsuitable for prints exposed to higher temperatures.

ABS

ABS is a thermoplastic known for its durability, strength, and high-temperature resistance, making it commonly used in the aerospace and automotive industries. Its versatility also makes it suitable for functional prototypes, electronic enclosures, and toys. However, it has some limitations, such as warping issues that require a heated bed to prevent cracking or warping. Moreover, it emits fumes when heated, requiring proper ventilation.

Despite its limitations, ABS has several benefits, including resistance to impact, wear, and high temperatures. It also has good layer adhesion, resulting in smooth and glossy finishes. Additionally, ABS comes in a wide range of colors and can be post-processed with sanding and painting. However, it's not biodegradable and can contribute to environmental pollution. Finally, ABS emits toxic fumes during printing that can be harmful if inhaled, making good ventilation essential.

TPU

Thermoplastic polyurethane (TPU) is a flexible and durable material that is resistant to wear and tear. It is used to create various flexible objects, such as phone cases and shoe soles. TPU is easy to print with and does not require a heated bed, making it a popular choice. TPU is also resistant to oils and chemicals. However, TPU can be more difficult to print with than other materials and may require some experimentation to achieve optimal results.

Benefits of TPU include its ability to create parts with high elasticity and impact resistance, as well as good layer adhesion. It has a low printing temperature and low warping, and is available in a range of colors with a soft-touch finish.

On the downside, TPU may require a slower printing speed and additional support structures. It is less heat-resistant than other materials, which may cause issues with prints that are subjected to high temperatures. Additionally, TPU can be prone to stringing and oozing, which may affect print quality.

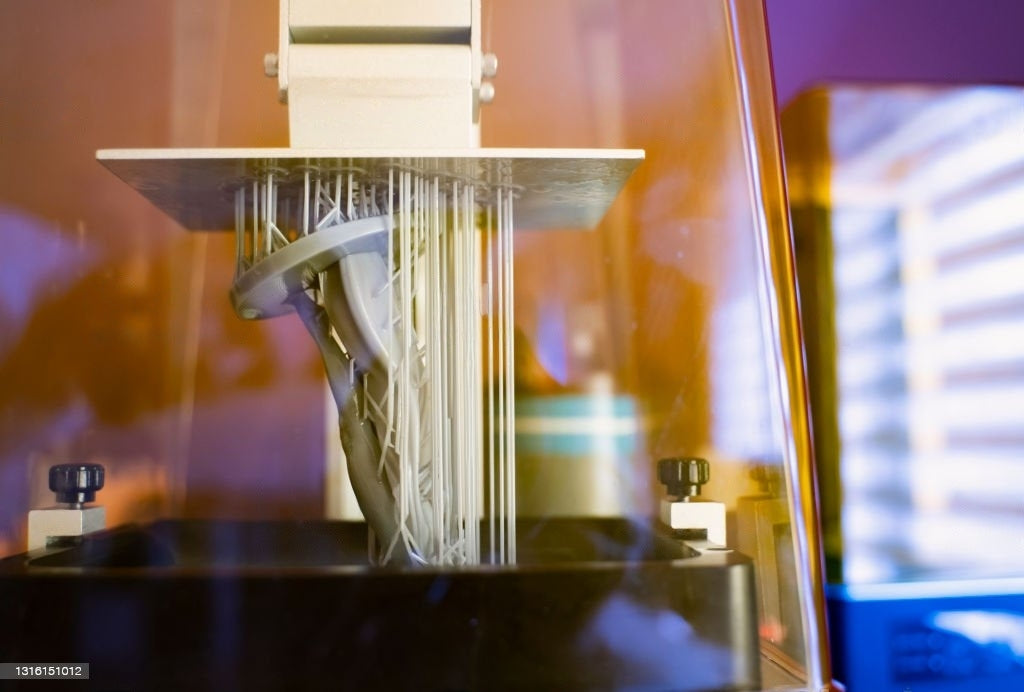

SLA Printing

Stereolithography (SLA) is a 3D printing technology that uses a laser to cure liquid resin into solid objects. It's ideal for creating high-detail, precise parts with a smooth surface finish.

Resin

Resin is a liquid photopolymer that cures when exposed to UV light. It's renowned for its ability to create complex geometries with high detail and smooth surface finishes. Resin is commonly used for creating figurines, dental models, and jewelry. Although there are various types of resin available, such as clear, opaque, and flexible, it's more expensive than other materials and requires a specialized printer. Moreover, it emits fumes when cured, making it essential to use it in a well-ventilated area.

The benefits of resin include its high level of detail and accuracy, making it a popular choice for creating prototypes and small-scale production parts. Additionally, it has a smooth and glossy finish and is available in a range of colors and finishes. Resin is also resistant to wear and tear and can withstand exposure to heat and UV light.

On the other hand, resin printing requires a high level of expertise and specialized equipment, which can be expensive. It's also more brittle than other materials and can be prone to cracking and breaking. Additionally, resin printing requires additional post-processing steps, such as washing and curing, which can be time-consuming.